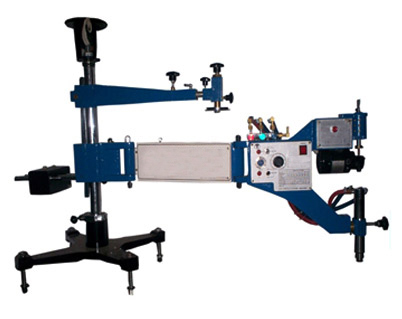

We are Authorised Dealer, Supplier, Service Provider of Manual Profile Cutting Machines, and our set up is situated in Pune, Maharashtra, India.

Shape Cutting Machine also known as Flame Cutting Machine or Manual Profile Cutting Machine. They are very useful for repetitive jobs, where they cut same profiles on a recurring basis. Template is cut on a thin sheet of Mild Steel or Stainless Steel. Then the template is mounted on the shape/flame/manual profile cutting machine. Tracer on the machine traces and guides the flame cutting torch to cut the mild steel plate put under the torch. Shape/flame/manual profile cutting machine has flexible arms, which can adjust the reach of the torch. It also contains beveling attachment.

This Machine is a small portable radial arm oxygen cutting machine. Being small in size and light in weight, the machine can be easily carried to the worksite and placed directly on the plate to be cut. As the machine is mounted on four ball castors, it can be moved about on the plate as required.

- This Machine is a light weight, portable yet robust shape cutting machine, which can be used on field job as well as in factories.

- The machine is designed with pantograph type arms, which keeps the hinge points of all the arms parallel to the line of the tracing roller and the torch, thus providing a direct line guiding system.

- This is simplest and one of the most accurate magnetic tracing systems, which help in maintaining repeatability of the flame cut parts.

- The precision ball and needle bearing design of hinges ensure free and frictionless tracing, hence enabling greater cutting accuracy.

- This Machine can cut shapes like stars, hexagons, squares, rectangles, triangles, straight lines etc and bevels up to 45 Degrees.

- The basic system of the machine enables the torch to duplicate any intricate shape provided on a template on the machine. The carriage arm consisting of a motor driven Electro Magnetic Tracing Head and a cutting torch travels round the template duplicating the exact shape of the template.

- The speed of the machine can be varied with an indexed selector knob. The tracing head can be moved in clockwise or anticlockwise direction by a selector switch.

- Incorporation of MIG / MAG, SAW or AC / DC TIG Welding features possible on request.

- Accurate & easy to operate. Solid state circuitry.

- Cutting (When Template is mounted on Template Holder) – 30mm to 740mm diameter.

- Cutting Area (When Template is mounted on Control Shaft) – 70mm to 2000mm diameter.

- Cutting Thickness - 3 mm to 150mm.

- Power Supply - 230 Volts AC, 50 Hz.

- Motor - 1/20 HP, AC/DC Series fractional Horse Power Motor.

- Control Design - SCR Speed Control System.

- Control Pointer - FWD OFF-REV Toggle Switch.

- Speed Control - Continuous variable by a rotary knob.

- Cutter Nozzles - Acetylene 'A' Type LPG 'B' Type.

- Cutter Movement - Vertical movement by Rack & Pinion.

- Gas connection - Oxygen -¼ G RH & Fuel -¼ G LH.

- Gross Weight - 58 Kgs (Approx).

Portable profile cutting machine model This Machine Suitable to cut metal based template from 30 mm diameter to 2 meter diameter, with speed control pot, forward / reverse, toggle switch and tracer, having special facility of inner & outer circle cutting facility just by pressing the tracer in front and weighing only 58 kg. MODEL: This Machine with gas torch.

- Cutting Torch with Holder

- Set of Cutting Nozzles.

- Set of Non-Return Valves.

- Set of Fuses.

- Set of Spanners, Keys.

- Counter Weight Block.

- Set of Nozzle Cleaner.

- Set of Tracing Rollers.

- Set of Hoses.

- Safety Gloves, Goggles.

- Spark Lighter.

- Gas Cutting Nozzle.

- Gas Cutting Torch.

- Oxygen and LPG / Acetylene.