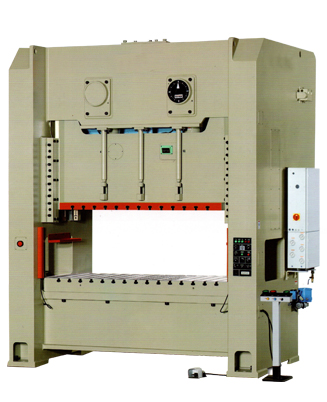

We are Authorised Dealer, Supplier, Service Provider of Cross Shaft H - Type, and our set up is situated in Pune, Maharashtra, India.

Advantage

- The symmetrical H Frame structure designed to resist deflection and is most suitable for progressive die application.

- Increase permissible off center loads

- High torque, wet clutch brake unit requires minimum maintenance, less air consumption, eliminates noise and significantly extends lining life.(Optional)

- These presses are most suitable for white goods & automobile components manufacturing

| Description | Model | |||||||||||||||

| H-Type-110 | H-Type-160 | H-Type-200 | H-Type-250 | H-Type-300 | H-Type-400 | H-Type-500 | ||||||||||

| Type | SG | HG | SG | HG | SG | HG | SG | HG | SG | HG | SG | HG | SG | HG | ||

| Capacity | tf | 110 | 160 | 200 | 250 | 300 | 400 | 500 | ||||||||

| Stroke Length Fixed (K) | mm | 160 | 100 | 200 | 130 | 220 | 150 | 250 | 180 | 280 | 180 | 300 | 200 | 300 | 200 | |

| Speed | Fixed | SPM | 50 | 80 | 40 | 60 | 35 | 50 | 30 | 45 | 30 | 40 | 25 | 35 | 25 | 35 |

| Varialble | 40 ~ 60 | 60 ~ 100 | 30 ~ 55 | 40 ~ 80 | 25 ~ 45 | 35 ~ 70 | 22 ~ 40 | 30 ~ 60 | 20 ~ 35 | 25 ~ 50 | 15 ~ 30 | 25 ~ 50 | 15 ~ 30 | 25 ~ 50 | ||

| Rating Point | mm | 5 | 3 | 6 | 4 | 7 | 4 | 7 | 5 | 7 | 5 | 7 | 6 | 7 | 6 | |

| Bolster Area (M x N) | mm | 1600 x 680 | 1800 x 800 | 2200 x 900 | 2500 x 950 | 2500 x 1000 | 2500 x 1100 | 2500 x 1200 | ||||||||

| Bolster Thickness (0) | mm | 135 | 160 | 170 | 180 | 190 | 200 | 200 | ||||||||

| Die Height (DH) | mm | 400 | 450 | 500 | 550 | 550 | 600 | 600 | ||||||||

| Slide Area (P x Q) | mm | 1350 x 600 | 1560 x 700 | 1850 x 800 | 2100 x 850 | 2100 x 900 | 2200 x 1000 | 2200 x 1100 | ||||||||

| Slide Adjustment | mm | 75 | 75 | 90 | 90 | 100 | 120 | 120 | ||||||||

| Side Opening (R x S) | mm | 500 x 400 | 550 x 400 | 640 x 450 | 700 x 450 | 750 x 500 | 850 X 550 | 850 x 550 | ||||||||

| Upright Distance (L) | mm | 1660 | 1860 | 2270 | 2570 | 2570 | 2570 | 2570 | ||||||||

| Main Motor | Fixed Speed | HPXP | 10 x 4 | 15 x 4 | 20 x 4 | 25 x 4 | 30 x 4 | 40 x 4 | 50 x 4 | |||||||

| Varialble Speed | HPXP | 15 x 4 | 20 x 4 | 25 x 4 | 30 x 4 | 40 x 4 | 50 x 4 | 60 x 4 | ||||||||

| Floor to Bolster Top (J) | mm | 900 | 900 | 1000 | 1000 | 1000 | 1100 | 1100 | ||||||||

| Foot Size (C x D) | mm | 2080 x 1200 | 2390 x 1350 | 2860 x 1550 | 3190 x 1650 | 3250 x 1760 | 3300 x 1950 | 3330 x 2050 | ||||||||

| Overall Space (H x I x E) | mm | 2400 x 2100 x 3100 | 2750 x 2300 x 3450 | 3200 x 2450 x 3900 | 3550 x 2700 x 4050 | 3600 x 2850 x 4250 | 3700 x 3000 x 4400 | 3800 x 3150 x 4650 | ||||||||

| Upper Die Weight | kg | 1000 | 1400 | 2000 | 2100 | 2350 | 2600 | 2800 | ||||||||

| Optional | ||||||||||||||||

| Pneumatic Die Cushion | Capacity | tf | 6 x 2 | 8 x 2 | 10 x 2 | 10 x 2 | 14 x 2 | 14 x 2 | 14 x 2 | |||||||

| Stroke Length | mm | 90 | 100 | 120 | 120 | 140 | 140 | 140 | ||||||||

| Pad Area | mm | 480 x 300 x 2 | 560 x 370 x 2 | 700 x 450 x 2 | 700 x 450 x 2 | 700 x 450 x 2 | 700 x 450 x 2 | 700 x 450 x 2 | ||||||||

Standard Accessories

- Motorised Grease Lubrication (PLC Controlled)

- Counter Balancer for slide

- Rotary Cam Limit Switch (Imported)

- Anti Repeat Safety through PLC

- Magnetic Production Counter (Imported)

- Dual Solenoid Valve (Imported)

- PLC based 24V DC Electrical Control Panel

- PLC with Fault Finding Facility

- Hydraulic Overload Safety (Imported)

- Die Height Indicator (Imported)

- Motorised Slide Adjustment

- Miss Feed Sockets

- Air Outlets

- Foot Switch

Optional Accessories

- Wet Clutch

- Knockout System

- Photo Electric Safety Guards

- Pneumatic Die Cushion (Bellow Type)

- Anti Vibration Mounts

- Variable Speed through VFD

- Quick Die Change System (Imported)

- 7" TOuch Screen with Tool Management

- Automation Line & Accessories

- Die Area Light

- Tonnage Monitor