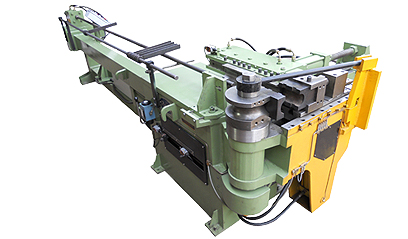

We are Authorised Dealer, Supplier, Service Provider of NC/CNC Pipe Bending Machines, and our set up is situated in Pune, Maharashtra, India.

Machine Features

- Die clamping with Toggle mechanism and Pressure die with direct acting hydraulic cylinder

- All slides guided on linear motion guideways

- Bend axis powered by hydraulic cylinder

- PLC system with touch screen HMI

- Increased push and bend speeds with optimized parallel axis motions for higher productivity

- Spring back compensation facility

Technical Specification

| Model | PL32 (3 Axis) | PL45 (3 Axis) | PL65 (3 Axis) | PL100 (3 Axis) | ||||

| Max Tube Capacity (D x T ) |

32 mm x 2mm (Ferrous tubes UTS 45 Kg/mm 2) |

45mm x 3mm (Ferrous tubes UTS 45 Kg/mm2) |

65mm x 5mm (Ferrous tubes UTS 45 Kg/mm2) |

114mm x 7mm (Ferrous tubes UTS 45 Kg/mm2) |

||||

| Min. Tube Capacity (D) | 6mm | 12mm | 20mm | 20mm | ||||

| Max. Bend Radius (CLR) | 120mm | 150mm | 350mm | 350mm | ||||

| Min. Bend Rdius (CRL) | 20mm | 25mm | 30mm | 30mm | ||||

| Min Bend Radius in terms of ( D ) | 1.5D | 1.5D | 1.5D | 1.5D | ||||

| Length Over Mandrel | 2 Meters | 2 Meters | 2.5 Meters | 4 Meters | ||||

| Carriage travel | 1.5 Meters | 1.5 Meters | 1.5 Meters | 2.5 Meters | ||||

| Bend Angle Range | 5 to 180 degrees | 5 to 180 degrees | 5 to 180 degrees | 5 to 180 degrees | ||||

| Bending Direction | Clockwise | Clockwise | Clockwise | Clockwise | ||||

| Max. Bend Speed (accuracy) | 30 degrees (± 0.2) | 30 degrees (± 0.2) | 30 degrees (± 0.2) | 30 degrees (± 0.2) | ||||

| Axis drives | Push & Turn - Electric AC Servo Bend - Hydraulically | Push & Turn - Electric AC Servo Bend - Hydraulically | Push & Turn - Electric AC Servo Bend - Hydraulically | Push & Turn - Electric AC Servo Bend - Hydraulically | ||||

| Axis (Programmable) | Max. Speed | Max Speed. | Max Speed | Accuracy | Accuracy | Max. Speed | Accuracy | Accuracy |

| Push (DBB) - Y Axis | 600 mm / sec | ± 0.1 mm | 600 mm / sec | ± 0.1 mm | 600 mm / sec | ± 0.1 mm | 400 mm / sec | ± 0.1 mm |

| Turn (POB) - B Axis | 200 deg / sec | ± 0.1 deg | 200 deg / sec | ± 0.1mm | 200 deg / sec | ± 0.1 deg | 120 deg / sec | ± 0.1 deg |

| Bend (DOB) - C Axis | 90 deg/sec | ± 0.2 deg | 90 deg/sec | ± 0.2 mm | 90 deg/sec | ± 0.2 deg | 30 deg/sec | ± 0.2 deg |

| PLC & Servo System | PLC, HMI & Servo systems of Mitsubishi make | PLC, HMI & Servo systems of Mitsubishi make | PLC, HMI & Servo systems of Mitsubishi make | PLC, HMI & Servo systems of Mitsubishi make | ||||

| Memory Capacity | 12 bends per program, 50 program | 12 bends per program, 50 program | 12 bends per program, 50 program | 12 bends per program, 50 program | ||||

| Connected Load | 5KW for Hydraulic & 2 KW for servo Motor | 5KW for Hydraulic & 2 KW for servo Motor | 7.5KW for Hydraulic & 3 KW for servo Motor | 15KW for Hydraulic & 4 KW for servo Motor | ||||

| Power Supply | 3 Phase AC, 415V, 50Hz | 3 Phase AC, 415V, 50Hz | 3 Phase AC, 415V, 50Hz | 3 Phase AC, 415V, 50Hz | ||||

| Oil Tank Capacity | 150 Litres (built in) | 150 Litres (built in) | 200 Litres (built in) | 300 Litres (built in) | ||||

| Machine Lubrication | Manual Centralized Lubrication System | Manual Centralized Lubrication System | Manual Centralized Lubrication System | Manual Centralized Lubrication System | ||||