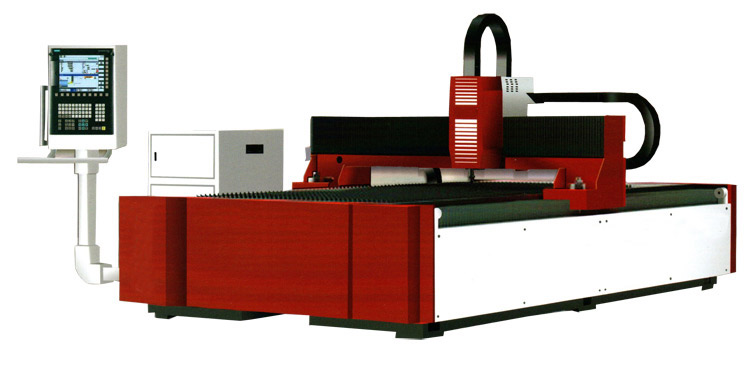

We are Authorised Dealer, Supplier, Service Provider of CNC Laser Cutting Machines, and our set up is situated in Pune, Maharashtra, India.

Featurs

- It adopts gantry-motion structure, linear guide, Screw drive, AC servo motor and drives, and vacuum system (both sides), etc. The one-time processing area is 3m x 1.5m. .

- Not only that the equipment's design is advanced and reliable, but also that all key components are from both national and international well known brands.

- In particular, we use Germany/Siemens/Japanese Fanuc's professional laser CNC system for the electrical control system

- This special laser CNC system has advantages of high integration, better control precision and more stable operation.

- Therefore, in addition to meet the requirement of cutting carbon steel plate, it can also meet the requirement of cutting SS plate, aluminum alloy, copper alloy and other materials.

- Mechanical motion systems of the laser cutting machine generally includes machine tool bed, beam and other basic components for the installation of laser cutting head.

- The Mechanical automatic processing is achieved through control system.

- The high quality Machine tool bed reduces laser equipment's vibration during the process of high speed operation.

- Equipped with waste collection drawers for slag discharging and dual ventilation dust pipe, the working table bears metal plates less than 500 k.g.

- The control system consists PLC and control cabinet, etc.

Functions

- Users-friendly operating interface

- USB port and broadband interfaces

- AC servo motor and drive

- Fast-response surface following

- Easy operated cutting retract function

- Straight line/circular arc interpolation fitting and kerf compensation functions

- Programming software Farley CNCKAD with automatic nesting functions

- CAD/CAM Software package with powerful nesting function and edge-shared cutting function

- Ventilation dust removal devices protect working environment from cutting emissions and metallic vapor

- Slag discharging devices facilitate slag discharging

Laser Source Has Following Advantages

- Maintenance free for no lens inside laser generator

- Beam delivery system consists of fibers

- Compact size and easy for integration

- No start-up time

- Excellent cutting ability

- Good beam quality and high power density

| Specifications | 3015 - 500 | 3015 - 750 | 3015 - 1000 |

| Table Size ( L x W ) | 1500 x 3000 mm | 1500 x 3000 mm | 1500 x 3000 mm |

| Laser Power | 500W | 750W | 1000W |

| Source Type | Fiber | Fiber | Fiber |

| Maximum Speed | 75m / min | 75m / min | 75m / min |

| Maximum Acceleration | 1G | 1G | 1G |

| Transmission | Double drive Rack Gear & Planetary gear box | Double drive Rack Gear & Planetary gear box | Double drive Rack Gear & Planetary gear box |

| Drive | Imported servo drive | Imported servo drive | Imported servo drive |

| Power Consumption | 10kW Max | 12kW max | 16kW max |

| Power Supply | 3 phase 380V / 50HZ / 60 HZ | 3 phase 380V / 50HZ / 60 HZ | 3 phase 380V / 50HZ / 60 HZ |

| MATERIALS THICKNESS (mm) | |||

| Carbon Steel | 4 | 6 | 8 |

| Stainless Steel | 2 | 3.5 | 5 |

| Aluminum | 2 | 3 | 4 |

| Copper | 1 | 1.5 | 2 |

| Brass | 2 | 3 | 4 |